Model SP7000 - Sand Probe

for High Pressure (HPTM and MHTM) Access Systems |

View data sheet (PDF) |

|

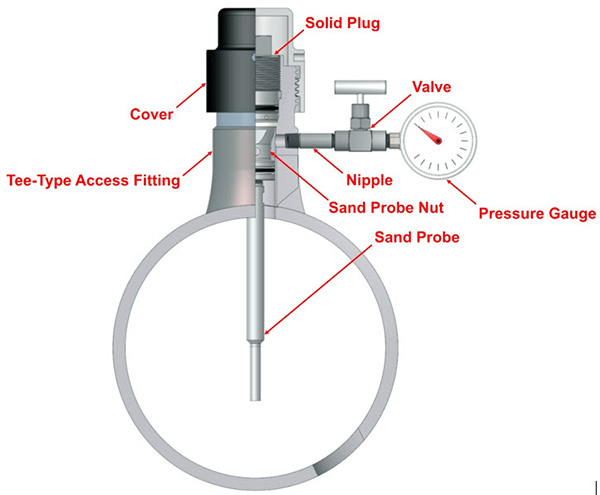

Model SP7000 sand probes are used to detect erosion in flow lines caused by abrasive particles such as sand. One end of the probe is attached to a tee-type, high pressure access fitting with a solid plug by means of a sand probe nut. The other end is a sealed, thin-walled tube placed within the process stream to be exposed to particulate flowing through the system. (To minimize the effects of corrosion and thus more accurately detect erosion within the stream, the exposed element is made of stainless steel.)

As particulate impinges on the surface of the sensing element, a hole is eventually eroded through the element. Once penetration has occurred, the system pressure then travels up the tube, into the access fitting body, and through a nipple and valve to a pressure gauge assembly. The pressure gauge detects that the element has been breached. If required, electronic pressure sensors can be connected to alarm systems to signal the exact moment when failure occurs.

(See Remote Alarm Actuator / Indicator.)

The insertion length (I.L.) can range from 3.75" up to any length specified by the customer in 1/4" increments. |

Specifications:

Probe Body - Stainless Steel

Temperature Rating - 500° F / 260° C

Pressure Rating - 3600 PSI / 245 Bar

Mounting - High Pressure (HP or MH) Access System with Solid Plug |

|

|

|

SP7000 Ordering Information

|

|

|

Sizing Formulas:

Shortest length available is 3.75 ".

Non-Flanged Access Fitting

(FH + PD/2) - (2.04 + N) = L

Flanged Access Fitting

(FH + PD/2 + MF) - (2.04 + N) = L

Where:

FH = Access Fitting Height

N = Injection Nut Length

L = Injection Tube Length

MF = Mating Flange Height

PD = Pipe Outer Diameter

|

Ordering Information for Sand Probe Nipples, Valves, Nuts, and Optional Parts

• Sand Probe Nipple

• Sand Probe Valve

• Sand Probe Nut

• Sand Probe Optional Parts - Pressure Gauge, Solid Plug

|