|

|

smartPIMS® Modbus |

View PDF version

|

non-intrusive ultrasonic sensors for corrosion/erosion monitoring |

Metal Samples along with Sensor Networks Inc., offers the smartPIMS® Modbus non-intrusive ultrasonic corrosion/erosion monitoring system which connects directly to a PC or laptop to take isolated measurements, or integrates with your SCADA/DCS system for polling at any user-defined time interval. Data can be readily transmitted to webPIMS™, a cloud based back-end for analysis and trending, or simply exported to XML or CSV as necessary for reporting purposes.

The smartPIMS® Modbus is used for:

• Infrequent data collection (mid-stream

applications).

• Hardwiring to a plant’s control system

(downstream or offshore).

• Service companies collecting data (refineries).

• Manual data collection (power generation).

monitor corrosion rate

resolution to 0.001” (0.025mm) • high-risk areas • historically problematic locations |

|

| |

|

monitor “low spots”

post-NDE screening of pits to monitor re-maining thickness • measures down to 0.040” (1.02mm) |

|

| |

|

replace/augment intrusive methods

validation of coupons, ER probes, etc. |

|

| |

|

reduce costs

reduce scaffolding and insulation removal/refitting for internal corrosion monitoring • more accurate/reliable data improving operations |

|

|

|

- Connects via Modbus (RS-485) to tablet/PC or

SCADA/DCS.

- Outputs data to XML or CSV file, or directly to

webPIMS.

- Up to 32 units connect on multi-drop network

extending as far as 1000’ (305m).

- Offers 16 single- or 8 dual-element UT probe

channels.

- Transducers available to withstand -22°F (-30°C ) to

932°F (500°C).

- Maintains 1 mil (0.001” / 0.025mm) resolution and

0.040” (1mm) minimum wall thickness.

- Sensors install buried or above-ground, temporarily or permanently.

- ATEX, IECEx, UL/CSA and Japanese hazardous-area certifications.

|

|

|

|

Technical Specifications

|

| Digital Sensor Interface |

|

| |

|

| Transmitter |

|

| Model: |

smartPIMS® Modbus |

| Protocol/Communication: |

Modbus / RS-485, 2-wire, max. 1000’ (305m) |

| Power: |

10-24 VDC |

| Ultrasonic System: |

Channels:

Pulser Voltage:

Analog Frequency:

Gain:

Digitizer Frequency:

Certification:

|

16 ultrasonic, 1 temperature

±5V bipolar square wave

1-10 MHz (-3dB)

-10dB to +70dB

40 Msps

Class I, Div. 2, Groups A-D, T4, Class 1, Zone 2, IIC, T4

II 3G, Ex ec IIC T4 Gc, Tamb -20°C to +60°C |

| Enclosure: |

Type: |

Instrumentation housing |

| |

Material/rating: |

Cast aluminum / NEMA 4X, IP66 |

| |

Temperature Range: |

-4°F to + 140°F (-20°C to +60°C) |

| |

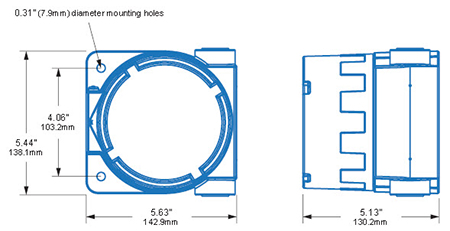

Dimensions: |

5.44 × 5.63 × 5.13” (138 × 143 × 130mm) |

| |

Weight: |

5.2 lb (2.36 kg) |

| |

|

|

| Tablet Datalogger |

|

| Performance: |

Processor:

Memory / Storage: Operating System: |

Intel i5-4200U 1.6GHz w/ 3MB L3 cache (dual-core) (min.)

8 GB RAM / M2-SATA SSD, 64 GB (min.)

Windows 10 |

| Connections: |

Network power, data via RS-485-to-USB adapter |

| Physical: |

Environmental ratings:

Dimensions:

Weight: |

IP65, MIL-STD-810G, 14 to 131°F (-10 to +55 °C) *

11.4” × 7.48” × 0.78” *

2.73 lbs. *

|

| * due to model changes, actual size/weight may change |

| |

|

| Transducers |

|

| |

|

| Transducer Cable: |

|

| Type: |

Coaxial, ¼” dia. |

| Maximum Length to Transducer: |

Standard 10’ (3.0m) and 25’ (7.6m), custom to 50’ (15.2m) |

| |

|

Transducers:

Model:

Application:

Frequency:

Active Area (dia.):

Overall (dia. x h):

# of transducers:

Resolution:

Thickness range**:

Temp. range:

Attachment: |

Dual-Element Contact

XD-301

Severe pitting

5 MHz

0.375” (10mm)

0.75” x 0.75” (19 x 19mm)

1-8

0.001” (0.025mm)

0.040 - 6.0” (1.0 - 150.0mm)

-22 to +275°F (-30 to + 135°C) magnet / adhesive |

Delay-Line Contact

XD-201

Ultra-High-Temp

7 MHz

0.375” (10mm)

0.8” x 2.25” (20.3 x 57.2mm)

1-16

0.001” (0.025mm)

0.125 - 1.0” (3.0 - 25.0mm)

-22 to +932°F (-30 to 500°C) mechanical clamp |

|

| |

| ** minimum resolutions stated as typical values, but will vary with pipe condition |

|

| |

|

|

|