|

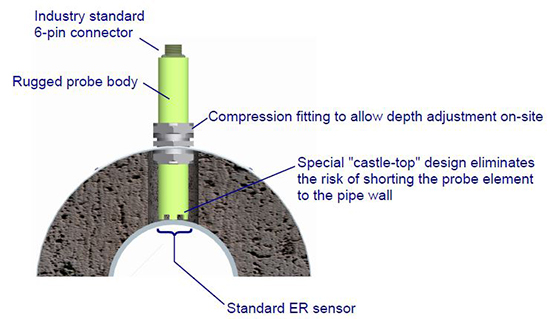

Model ER0600 Corrosion Under Insulation (CUI) probe is designed for measuring corrosion behavior under the insulation of jacketed pipes where corrosion may go undetected for long periods of time, resulting in unsafe operating conditions, equipment failures, and costly repairs.

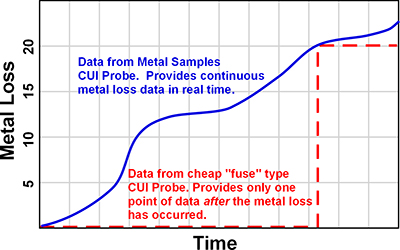

Unlike other CUI probes which are retrospective and only alert you after a certain level of corrosion has been reached, the model ER0600 is a true ER corrosion probe which provides continual, real time corrosion data (metal loss). Being a standard ER probe, it can be measured with any standard ER meter. |

|

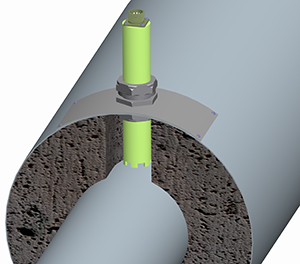

The ER0600 CUI probe utilizes a flush ER element which can be inserted through the outer pipe jacket and insulation layer, and located adjacent to the pipe surface where corrosion may occur. The unique castle-top design helps to facilitate installation and set the proper spacing for the element, while preventing contact between the probe element and the pipe wall.

|

|

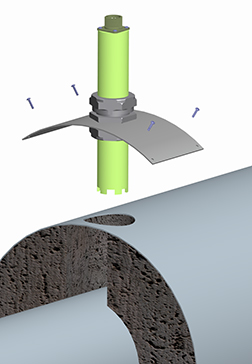

The probe is provided with the necessary sheet metal mounting flange and compression fitting. Installation requires a single hole to be cut in the pipe jacket and insulation. Then the mounting flange is secured to the pipe jacket with standard sheet metal screws. The compression fitting holds the probe in place after it has been set to the desired depth. |

|

|

| Specifications: |

|

| Probe Body Material: |

FRP / Epoxy |

| Element Material: |

Carbon steel standard. Others available. |

| Temperature Rating: |

300° F / 150° C |

| Element Thicknesses: |

5 mil, 10 mil, 20 mil, 40 mil |

Key Features:

- Provides real-time metal loss data, allowing users to identify and mitigate corrosion problems as they occur.

- Compatible with standard ER corrosion meters.

- Easy to install and replace.

- Adjustable depth to accommodate different insulation thicknesses.

- Rugged design to withstand industrial and plant environments.

|

Data comparison of

Metal Samples CUI probe vs. "fuse" type CUI probes |

| |

|

|

|

ER0600 (CUI Probe) Ordering Information |

|

| |