Coupons can be furnished with a variety of finishes depending on your particular application. Some of the typical finishing processes are explained below.

|

Glass Beaded – Coupon surfaces are blasted with fine glass beads to remove mill scale. This typically results in a finely textured surface with a typical surface roughness of approximately 50 µIn RA on steel coupons*. Glass beading should remove any mill scale and surface corrosion, but it may not remove all surface defects such as scratches. While not perfect, glass beaded coupons have a much better surface compared to a mill finish and provide more consistent surfaces. The glass beaded surface finish is very economical and is our most popular surface finish. |

| |

|

|

Coarse Grit Blasted – Coupon surfaces are grit blasted using a coarse media such as aluminum oxide to remove mill scale. This also results in a textured surface, but it is coarser than a glass beaded surface. Typical surface roughness will be 65-70 µIn RA on steel coupons*. Coarse grit blasting also removes mill scale and surface corrosion and does a better job of removing surface defects such as scratches compared to glass beading. |

| |

|

|

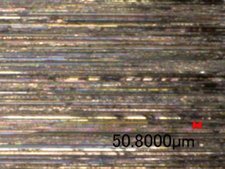

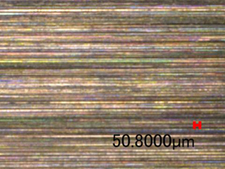

Sanded – Coupons are finished using a directional sanding process. A wide range of surface roughness can be achieved by using different grit sizes. A 120 grit belt is standard and is commonly used in corrosion tests. This results in a typical surface roughness of 125-130 µIn RA on steel coupons*. If a smoother surface finish is desired, finer belts such as 400 grit and 600 grit can be used. Sanded coupons will exhibit a linearly directional finish and may exhibit slight beveling along the edges. |

| |

|

|

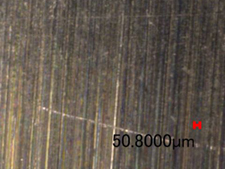

Double Disc Ground – Coupons are finished between two counter-rotating grinding stones, resulting in an extra-fine finish. This process is more expensive, but results in a superior, more repeatable surface finish compared to the other methods. Double Disc Ground coupons will exhibit swirled grinding marks on the faces and have a typical surface roughness of 35-40 µIn RA on steel coupons*. Finished surfaces should be free of contaminants and defects. This option is excellent for studies where surface finish or repeatability is critical. |

| |

|

|

Lapped – Coupons are machine finished on a lapping plate using a lapping compound to produce a very flat and smooth surface. Lapping can achieve surface roughness as low as 3-5 µIn RA on carbon steel*. This method produces one of the best surface finishes but is more expensive than other methods, including grinding. |

| |

|

| * Surface roughness listed is for reference purposes only. Actual surface roughness will vary depending on the material and condition. |

A note on surface finish

It is important to note that the items described above are finishing processes and not actual surface finishes. A true surface finish callout will specify the required surface roughness in a measurable unit such as RA or RMS. If coupons

are ordered by a finishing process such as “120-grit sanded” then Metal Samples provides coupons finished using that process, but the actual surface roughness is not controlled. Coupons can be ordered with a specific surface roughness

if that is required, in which case Metal Samples will select the appropriate method(s) to achieve the desired roughness.

|