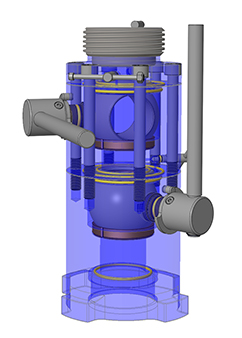

The Double Block Service Valve mounts on top of a

mechanical access fitting and provides temporary containment and control of the pipeline media, as well as the mounting point for the mechanical retrieval tool during installation/retrieval

of monitoring devices. The double block service valve has two ball and seat assemblies, each one of which provides

complete isolation of the pipeline media, thus providing an extra layer of safety in the unlikely event that one of the seats fails.

Our double block service valve also allows controlled pressure equalization between the pipeline side and retriever side. There are two bypass needle valves: one for the lower ball and seat assembly and one for the upper. Pressure equalization reduces the torque required to operate the valve. It also reduces stresses from fast pressurization, thus extending the lives of the seats, o-rings and valve components.

|

|

If the plug cannot be removed, or if a longer term sealing is required, a blanking cap/plug assembly can be installed on the valve as an additional safety measure. However, the service valve is not

designed to be mounted permanently.

The double block service valve is manufactured from 17-4 PH stainless steel and other

materials that meet NACE MR0175/ISO 15156 standards. The weight of the valve is approximately 50.7 lbs./ 23kg.

The service valve comes as a kit in a durable molded polymer field service container and includes a non-spark hammer, a spare seals kit, an extension bar and a tool kit.

|

|

Ordering Information |

|

| |

| Accessories / Spare Parts / Optional Components chart |

| Description |

Material |

| Service Valve repair kit (main seats, secondary seats, o-rings, valve balls) |

Glass filled PTFE, FKM elastomer,

14-4PH |

| Service Valve seal kit (main seats, secondary seats, o-rings) |

Glass filled PTFE, FKM elastomer |

| Service Valve ball |

17-4PH |

| Accessory kit (brush, hammer, hex wrenches) |

Various |

|

|