|

|

MS2801L - CorrTran MV

LPR RS-485 Modbus Transmitter |

View data sheet (PDF)

User's Manual (PDF)

Instrinsic Safety Certifications

|

Metal Samples’ MS2801L CorrTran MV transmitter

measures general corrosion, localized corrosion (pitting), and conductance, and transmits that information to operators via RS-485 Modbus protocol in real time.

The CorrTran MV utilizes state-of-the-art algorithms and data analysis techniques to accurately measure general corrosion rate and pitting. Harmonic distortion analysis (HDA) is applied to improve the performance of the

industry-accepted linear polarization resistance (LPR) technique used to measure corrosion rate.

To further enhance the performance, an application specific

Stern-Geary variable (B value) is calculated and updated every measuring cycle. There is no need to manually update the B value because of process changes. During the measurement cycle, CorrTran MV also performs an automated electrochemical noise (ECN) measurement, which in combination with the corrosion rate data can provide a measurement of localized corrosion (pitting).

The CorrTran MV works with Metal Samples three-electrode CorrTran style probes and electrodes. Probes are available in a variety of mounting types and materials

to suit almost any type of installation. |

|

| Features |

- On-line corrosion monitoring, multivariable

- RS‐485 Modbus

- General corrosion, localized corrosion (pitting), and conductance monitoring

- Stern-Geary B value automatically updated for changes in the process

|

|

|

|

|

Technical Specifications

|

| Model |

MS2801L CorrTran MV - LPR RS-485 Modbus Transmitter |

| |

|

| Physical Data |

|

| Instrument Weight: |

3.70 lb (1.67 kg)* |

| Instrument Dimensions: |

8.00” x 4.82” x 3.45” (20.32cm x 12.24cm x 8.76cm) |

| Operating Temperature: |

-40° to 158°F (-40° to 70°C) |

| Enclosure Material: |

Cast Aluminum (Copper‐Free) / Stainless Steel 316 |

| Degree of Protection: |

IP66, NEMA 4X |

| Electrical Entry: |

3/4 NPT (Other entries available on special request) |

| * Aluminum |

|

| |

|

| Electrical Data |

|

| Electrical Connection: |

Power and RS‐485 Serial communication |

| Minimum terminal voltage: |

11 V |

| Maximum terminal voltage: |

30 V |

| Current Consumption: |

~30mA |

| |

|

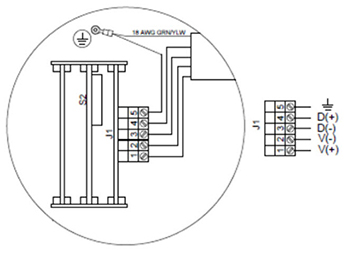

| Terminal Assignments |

|

| |

|

| Measurement Data |

|

| Probe Type: |

3-Electrode LPR |

|

|

|

|

| Measurement Type: |

General Corrosion |

|

Localized Corrosion |

|

Conductance |

| Measurement Unit: |

mpy (mils per year) or

mmpy (mm per year) |

Unitless |

microSiemens (µS) |

| Measurement Range(s): |

Default Range:

0 to 40 mpy

(0 to 1 mmpy) |

Default Range:

0.0 to 1.0

Low Range:

0.0 to 0.3

High Range: 0.3 to 1.0 |

5 to 333,333 |

| |

Maximum: 1000 mpy

(25 mmpy) |

|

|

| |

|

|

|

| Maximum Measured Error: |

Excitation voltage < 0.05% of full span

Corrosion current measurement <0.2% of full span |

| Factory Settings: |

B value (Stern Geary value): 25.6 mV

K value (corrosion constant): 11800 (2e- in reaction) |

| Measurement Cycle: |

4 to 21 minutes (depends on configuration) |

| Output Data |

|

| Output Signal: |

RS‐485 Modbus RTU and ASCII protocol |

| Baud Rate: |

2400/4800/9600/19.2K selectable |

| Address: |

32 Maximum Units (addresses 1 to 32) |

| |

|

| Enclosure Specifications |

|

| Explosion Proof: |

FM, CSA, CENELEC, UL |

| Protection: |

IP66, NEMA 4X, 7BCD, 9EFG |

| |

|

| Hazardous Location Certifications |

|

| Type of Protection: |

II 2(1) G

Ex db[ia Ga] IIC T5….T4 Gb

‐40⁰ C ≤ Ta ≤ + 80⁰ C

Ex db[ia Ga] IIC T6 Gb

‐40⁰ C ≤ Ta ≤ + 70⁰ C |

| |

|

| Conformity Information |

|

| Directive 2014/34/EU (ATEX): |

EN 60079-0 , EN60079-1 , EN 60079-11 |

| |

|

EC-Type Examination Certificate, Statement of Conformity, Declaration of Conformity, Attestation of Conformity and instructions have to be observed where applicable. For information contact Metal Samples.

|

|

MS2801L CorrTran MV Ordering Information

|

|

|

| |

| |

|

|

|