Laser Tube Cutting Services |

Videos

|

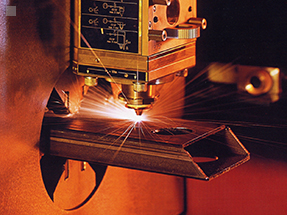

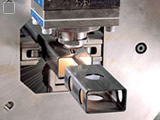

Laser tube cutting services from Alabama Laser are performed with three CO2 laser systems designed for cutting round, square, rectangular, flat, oval, and virtually any other type of tubes. Laser tube cutting services from Alabama Laser are performed with three CO2 laser systems designed for cutting round, square, rectangular, flat, oval, and virtually any other type of tubes.

Our laser tube cutting systems enable us to cut slots and holes in round tubing with diameters up to 8 5/8" (minimum O.D. of 1/2") and square tubing with side dimensions up to 8".

Maximum

tube wall thickness = 5/8" on carbon steel and 1/4" on stainless & aluminum..

These laser tube cutting systems allow storage of tube bundles and can automatically load and position tubes with lengths between 10.5' and 24.5' without operator intervention. Shorter and longer tube lengths can be loaded manually (up to 27.5'). |

Benefits of Laser Tube Cutting:

- No tooling expenses

- Minimal burrs or chips on cuts

- Coolant-free (no cutting fluid

residue left on parts)

- Accurate tolerances (repeatability)

- Multiple operations can be

consolidated into one cycle

- Small to large production runs

- Conserve material by nesting several

parts into the length of one tube

- Ability to be run unattended

|

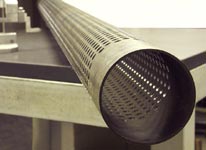

Laser cut tube - 9 ft. long / 3,000 holes |

|

Square Tube Cutting Square Tube Cutting |

Round Tube Cutting Round Tube Cutting |

Rectangular Tube Cutting Rectangular Tube Cutting |

Special Shape Tube Cutting Special Shape Tube Cutting |

|

| |

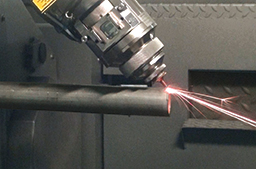

| Tilting Axis for Beveled Cuts |

|

|

|

| Our latest laser tube cutting system has a tilting axis which allows for angled cuts. In the past, if chamfered holes were required on tube parts, a secondary machine shop operation would be required. Now the bevel can be made with the laser tube cutter. |

|

| |

Chamfered Hole Cutting Capabilities of Laser Tube Cutting System

|

| |

Coping Cabilities of Laser Tube Cutting System

|

|

| |

Tab & Slotting Cabilities of Laser Tube Cutting System

|

|

| |

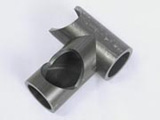

Brackets laser cut from tubing |

Previously cut on CNC swiss

screw machine in 10 min.

Laser tube cut in 56 sec. |

With conventional

machining - multiple processes.

With the laser tube cutter -

only 1 cycle is needed. |

|