|

|

|

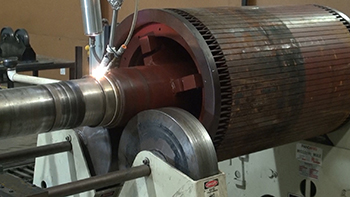

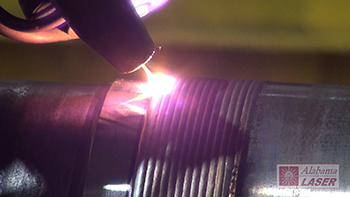

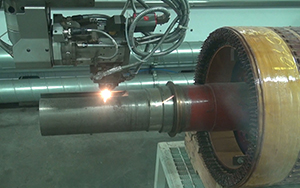

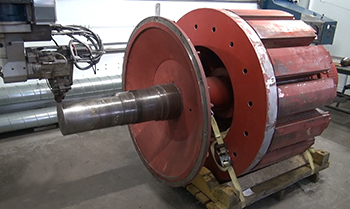

In comparison to heat inducing technologies, such as conventional plasma weld overlay, laser cladding uses low heat that doesn’t affect the concentricity or cause warpage of the shaft. After being clad, the repaired area may then be post-machined back to print specification.

Unlike metalizing processes that produce a mechanical bond which can flake off, the durable clad produced with lasers is a metallurgical bond that will not flake off during assembly or in process. Laser cladding also allows alloys to be added to strategic areas on the shaft to eliminate problems such as wear and corrosion.

Badly damaged shafts can be laser clad to build the shafts up to original specifications. Using laser cladding we are able to salvage otherwise scrapped shafts. |

|

| |

|

|

|

| |

|

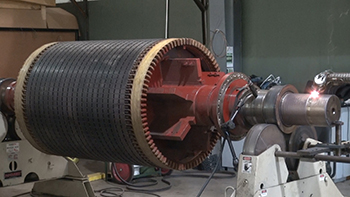

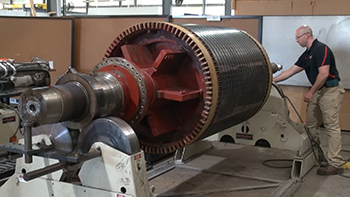

Alabama Laser repairs electric motor shafts for:

- Bearing journal wear due to a bearing “spinning”

on the

shaft during operation

- Bearing failure/seizure during operation

- Damage caused during assembly/disassembly

- Damage as a result of corrosion during service

- Machining errors

|

|

| |

|

|

| |

|

|

| |

|

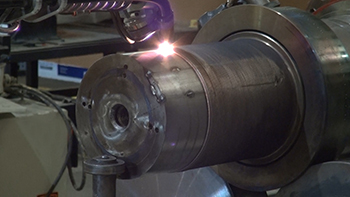

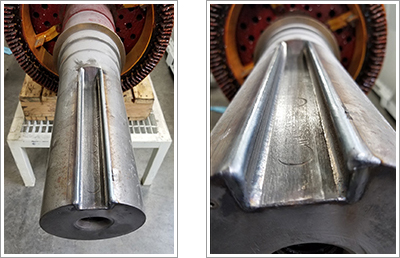

Alabama Laser uses laser cladding technology to repair oversized or worn keyways on electric motors.

Instead of having to plug, weld, and re-machine keyways, our laser cladding equipment can be programmed to build-up the profile edge of the keyway area. The laser cladding repair may then be post-machined back to print specification. |

|

| |

|

|

|

| |

|

|

|

| |

|

|

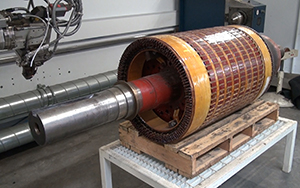

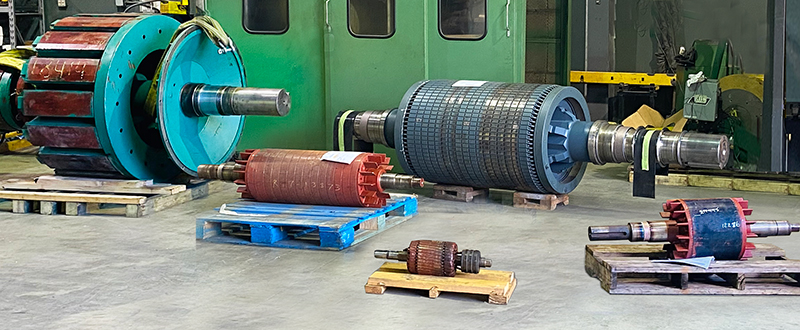

Various sizes of electric motors lined up for repair. |

|

|

| |

|

| |

|