|

Alabama Laser

offers specialized laser process development and

laser research services. Our in-house

engineering team is devoted to providing solutions for laser machining problems, including

system development and process development for laser cutting, welding, etching, heat

treating, and cladding.

Process Development & Laser Research Projects include: |

|

|

|

Metal

Deposition

Process development for metal powder deposition using fiber-delivered, direct diode

lasers. Applications include repairing parts that have been damaged through the wearing

away of surface metal.

More on laser metal deposition. |

|

|

|

Laser Heat

Treating / Hardening

Heat treating applications to change the

hardness of materials.

More on laser heat treating. |

|

|

|

Fiber

Lasers

Development of new applications using the specialized beam performance of fiber lasers.

More on fiber lasers. |

|

|

|

Hybrid Welding

Our laser research team has

worked to help develop a hybrid welding system which utilizes the welding

capabilities of a 10,000 Watt fiber laser and a MIG welder.

More on hybrid

welding. |

|

|

|

Laser

Blanking

Research on high-speed laser blanking for the automobile industry. |

|

|

|

Improving

Cut Quality

We work with companies to improve the cut quality of their laser systems using gas dynamic

beam analysis and development of custom components, including beam directors, beam

benders, cutting heads and welding heads. |

|

|

|

Weld

Process Development

Using CO2, Nd:YAG, fiber, and direct diode laser systems, the Alabama Laser research team

continues to make advancements in laser welding process development for both diffusion and

keyhole welding methods. |

|

|

|

Robotic Systems Applications

Combining robots, our beam delivery systems, and the technology of fiber

lasers and direct diode lasers, we have explored new applications for

cutting, welding, and laser hardening. The flexibility of fiber lasers and

the compact size of direct diode lasers enable robots to be used as an

effective motion system for laser material processing. |

|

|

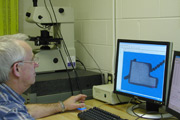

Metallurgical Laboratory |

|

|

With our state-of-the-art metallurgical lab we are able to offer a range of

analytical and consulting services.

More |

|

|

Alabama

Laser Systems

A Branch of Alabama Specialty Products, Inc.

P.O. Box 55

55 Laser Blvd.

Munford, AL 36268

Phone:

(256) 358-9055

Fax: (256) 358-4515

E-mail: als@alspi.com

Return

to Alabama Laser homepage

|